PRODUCT

Crane & Hoist SystemOur Crane & Hoist Systems are designed to handle heavy loads safely and efficiently. Ideal for factories, warehouses, and construction sites, they provide reliable lifting solutions that enhance workflow and productivity.

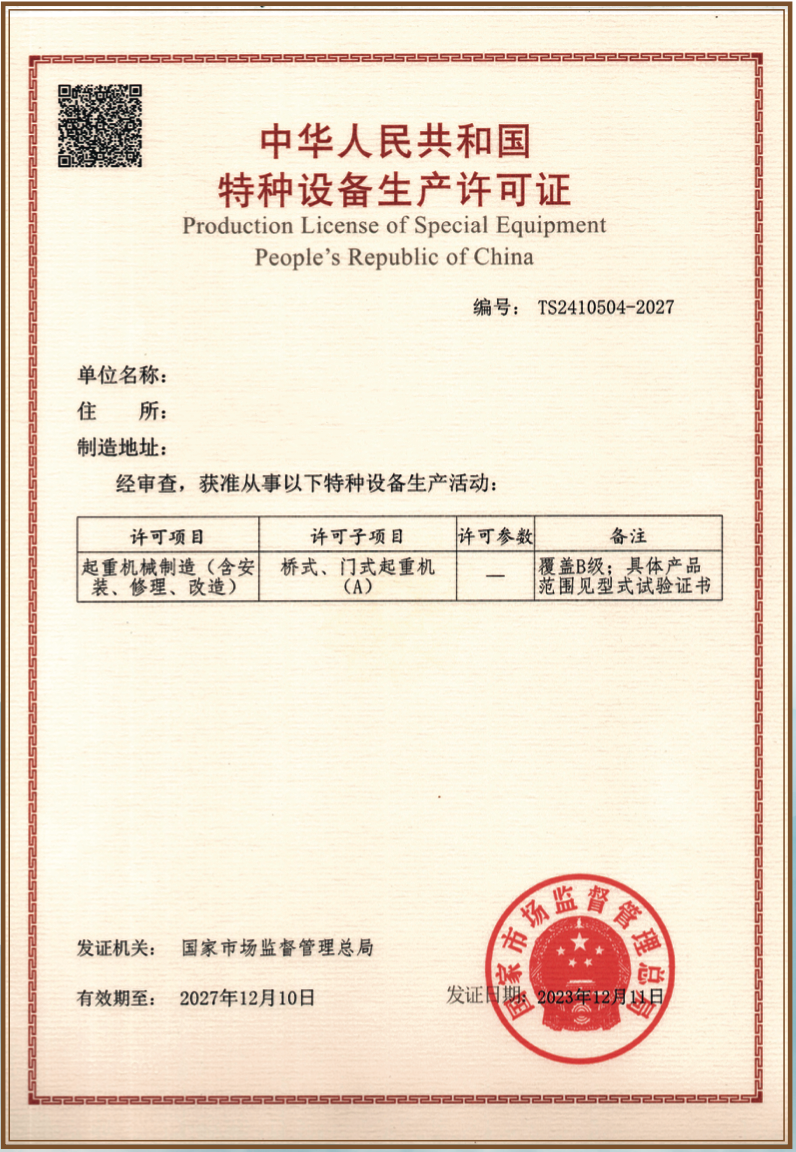

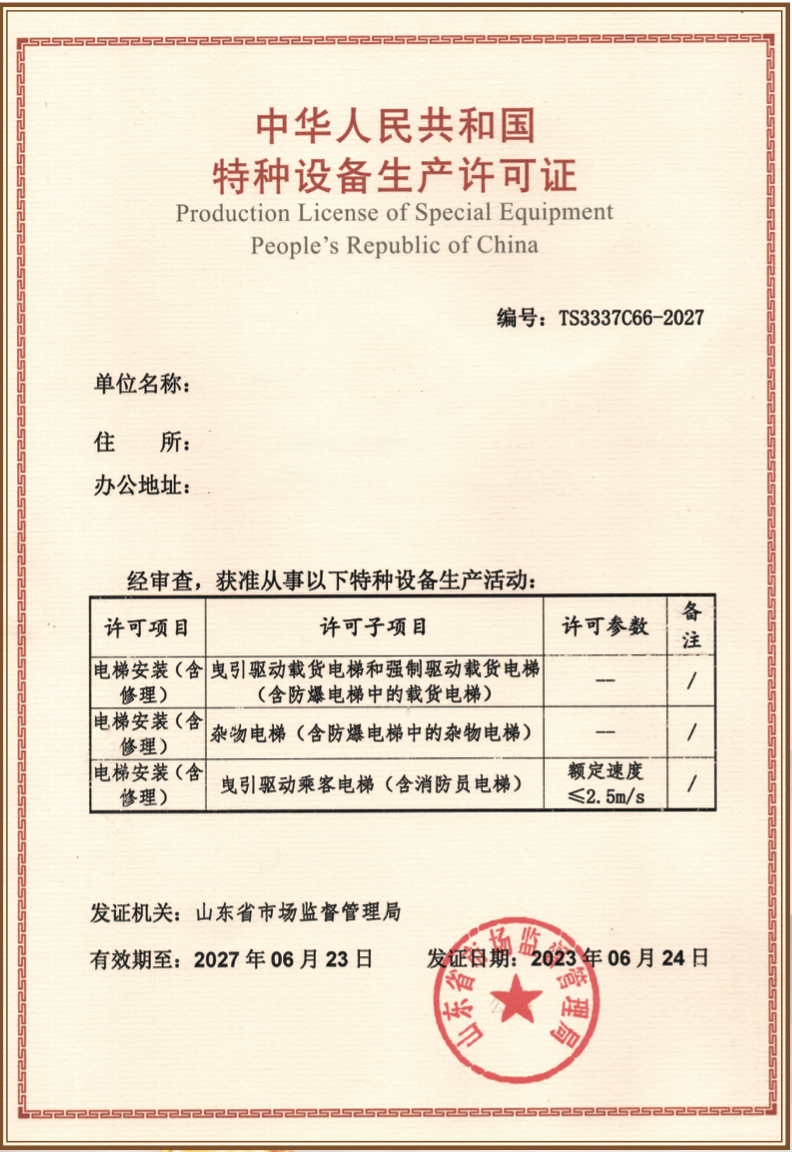

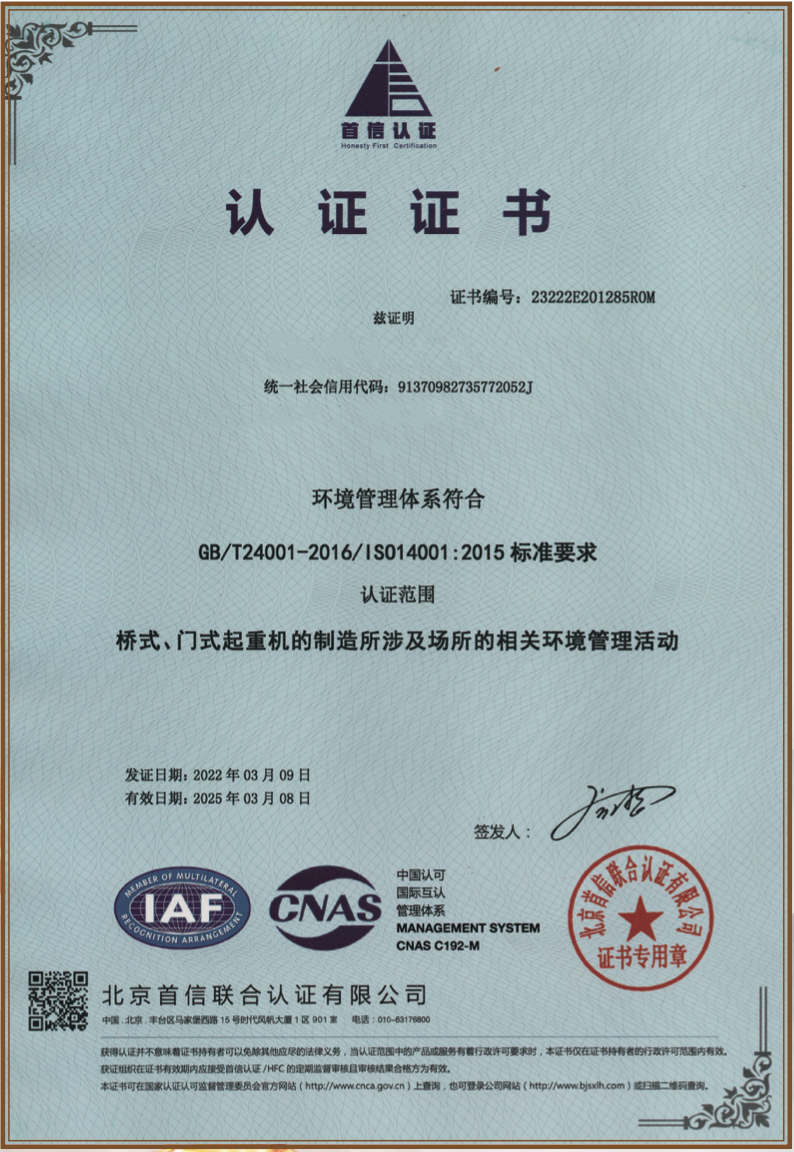

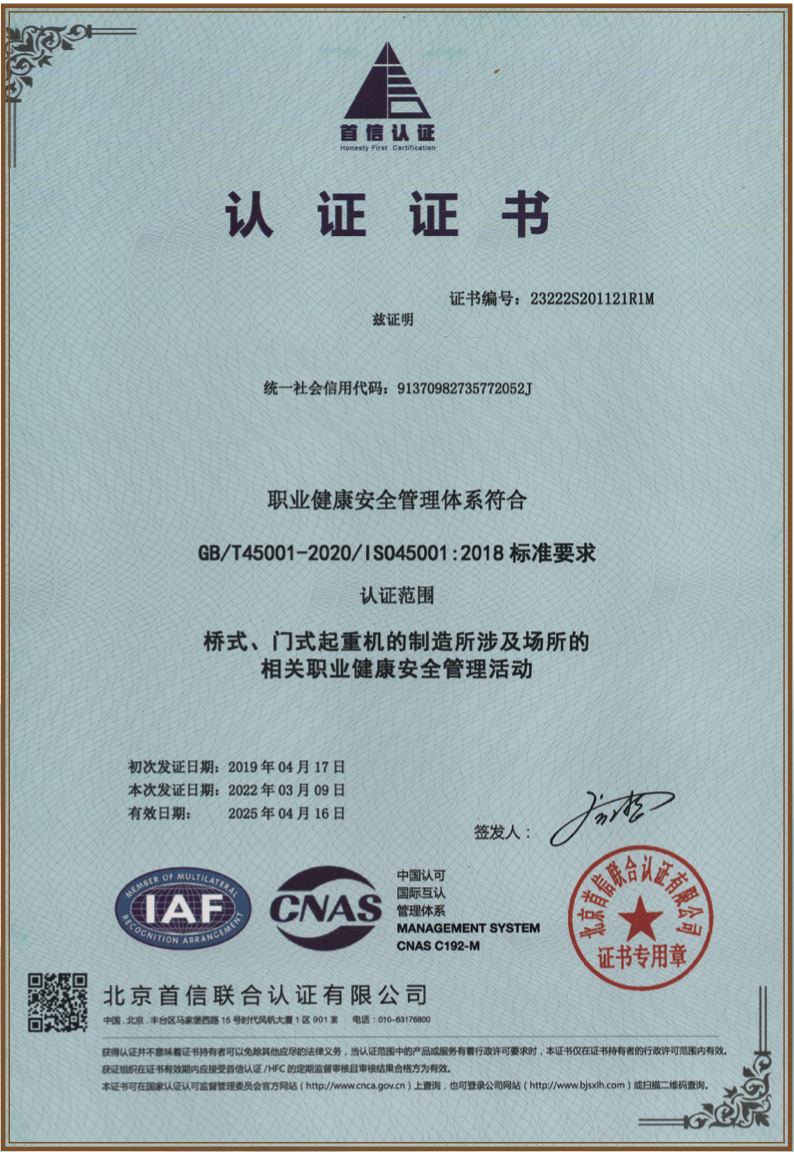

OUR CERTIFICATES

OVERHEAD CRANE SERIES

European Type Double Girder Overhead CraneThis product series is developed with the goal of achieving lightweight crane structures. By incorporating advanced design theories such as optimization design and reliability engineering, and by adopting new materials, technologies, and manufacturing processes, the series implements a modular design approach. As a result, it offers a new generation of bridge cranes characterized by a high degree of standardization, serialization, and interchangeability, representing an upgraded product line that supports the sustainable development of China’s crane industry.

This series features a lightweight structure, compact dimensions, and low energy consumption. While significantly reducing steel usage and power demand, it also lowers building construction requirements for the plant. Overall, its technical performance has reached an internationally advanced level.

OVERHEAD CRANE SERIES

European Type Single Girder Overhead CraneThe European-style electric single-girder crane features a lightweight, compact design with reduced wheel loads. Compared with traditional cranes, it offers a smaller hook-to-wall distance and lower headroom, allowing closer operation and greater effective workspace within existing facilities. The crane uses a three-girder split structure, with the main and end girders connected by high-strength bolts, ensuring a light yet durable design with high assembly accuracy and easy transportation and installation.

Its integrated end girder is machined in a single process to keep wheel skew within tolerance, ensuring smooth operation and extending both crane and building service life. The crane travelling system adopts a “three-in-one” motor-gearbox-brake drive with dual-side operation, offering high transmission accuracy, low noise, long lifespan, and maintenance-free performance

GANTRY CRANE SERIES

MG-Type Double Gantry CraneThe MG-type double-girder gantry crane is a variant of the double-girder bridge crane, primarily used for outdoor operations such as loading and unloading cargo, materials, and bulk goods.

Its metal structure forms a portal frame, with two supporting legs mounted beneath the main girders, allowing the crane to travel directly on ground rails. The main girder ends can also be equipped with cantilever extensions. This design offers high space utilization, a large working range, wide adaptability, and strong versatility, making it widely used in port and freight yards.

GANTRY CRANE SERIES

RMG Ravvil-Mounted Container Gantry CraneA rail-mounted container gantry crane consists of double main girders, a rigid leg, a flexible leg, a hoisting trolley, a hoisting winch, a dedicated container spreader, crane bogies, an electrical system, and an operator’s cabin. The gantry structure provides a large clear span between the legs, achieved through a U-shaped open upper section and interconnected leg tops, with a trolley maintenance platform installed above.

Depending on the application site, the crane can be configured without cantilevers or with single or double cantilevers. The hoisting trolley can incorporate both upper trolley rotation and lower spreader rotation. This type of crane is primarily used in railway transfer yards, port terminals, and large container storage yards for loading, unloading, transporting, and stacking containers. It is capable of handling 20-ft, 40-ft, and 45-ft ISO standard containers

GANTRY CRANE SERIES

MH Type Electric Hoist Gantry CraneMH-type electric hoist gantry cranes are paired with CD, MD, HC and other electric hoists. They are rail-mounted medium- and small-sized lifting equipment. The crane consists of the gantry frame (main beam, legs, lower crossbeam, etc.), hoisting mechanism, traveling mechanism and electrical system. The electric hoist serves as the lifting mechanism and travels along the I-beam flange of the main beam. It is suitable for lifting capacities of 3–32 tons, spans of 12–30 meters, and operating temperatures from –20°C to +40°C.

This model is a general-purpose gantry crane, commonly used in open yards and warehouses for loading, unloading or material handling. It can be operated either from the ground or a cabin, depending on user requirements.

GANTRY CRANE SERIES

MDG Type Gantry CraneThe MDG-type gantry crane consists of the gantry frame, trolley, crane traveling mechanism, operator’s cabin, and electrical control system. The gantry adopts a box-type structure, with the trolley running on one side of the main beam. For lifting capacities below 20 tons, the trolley uses a vertical anti-derail roller design; for capacities above 20 tons, a horizontal anti-derail roller design is used. The main beam features a single-beam, offset rail structure, while the support leg is L-shaped, providing a large lifting space and strong outreach capability, making it easy to transfer loads from inside the span to under the cantilever.

This crane is widely used in factories, mines, enterprises, railway stations, and ports. It offers advantages such as light self-weight, reduced material usage, lower cost, and a smaller windward area.

GANTRY CRANE SERIES

MHH Type Electric Hoist Truss Gantry CraneMHH-type electric hoist gantry crane is a rail-mounted medium-and small-scale lifting device. It is mainly composed of the gantry frame (main beam, legs, lower crossbeam, etc.), hoisting mechanism, traveling mechanism, and electrical system. The electric hoist serves as the lifting mechanism and operates along the lower flange of the I-beam on the main beam.

The truss structure features low self-weight and strong wind resistance. Overall, the crane offers light weight, simple structure, and easy installation and maintenance. It is suitable for general loading, unloading, and lifting work in factories, storage yards, and outdoor warehouses within the medium and small lifting capacity range

GANTRY CRANE SERIES

MBH Type Electric Hoist Semi-Gantry CraneThe MBH-type electric hoist semi-gantry crane is designed to work with CD, MD, HC and other types of electric hoists. It is a rail-mounted medium- and small-sized lifting device. The crane consists of the gantry frame (main beam, leg, lower crossbeam, etc.), hoisting mechanism, traveling mechanism, and electrical system. The electric hoist serves as the lifting mechanism and travels along the lower flange of the I-beam on the main beam.

One side of the gantry is equipped with a support leg that runs on the ground rail, while the other side has no leg and operates on the elevated runway of the workshop. All other structures and configurations are consistent with those of the MH-type electric hoist gantry crane

GANTRY CRANE SERIES

MHC Type Side-Mounted Electric Hoist Gantry CraneThe MGH-type gantry crane, also known as a girder launcher, is a gantry crane specially designed for bridge construction. It is mainly composed of modular main girders, support legs, and a trolley. The components are connected with pins and high-strength bolts, making assembly, disassembly, and transportation convenient. Compared with standard gantry cranes, this model offers faster installation, greater practicality, and better cost efficiency, making it particularly suitable for road and bridge construction units that frequently relocate

GANTRY CRANE SERIES

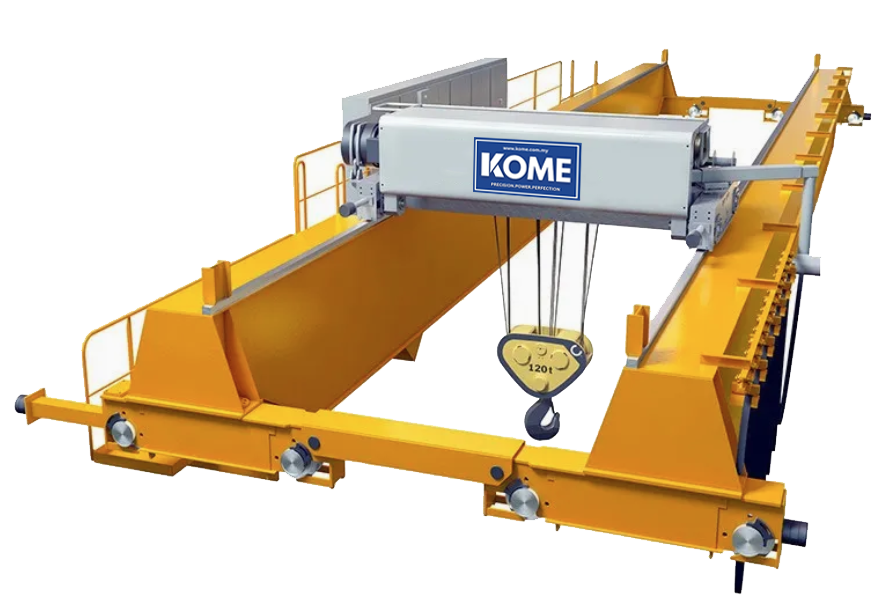

QD Type Hook Bridge CraneThe QD-type hook bridge crane operates through three motions: the crane’s longitudinal travel along the runway beams, the trolley’s transverse travel, and the hook’s lifting movement. Common lifting capacities range from 5 to 200 tons, with working classes from A5 to A7.

Three operating modes are available: wired pendant control, cabin operation, and wireless remote control. Class A5 is suitable for general mechanical machining and assembly workshops, metal structure workshops, and maintenance shops where the workload is moderate. Classes A6 and A7 are suitable for more frequent or continuous handling operations, and may also serve as auxiliary lifting equipment in metallurgical and foundry workshops. The allowable operating temperature ranges from –20°C to +40°C.

GANTRY CRANE SERIES

QZ Type Grab Bucket Bridge CraneThe QZ-type grab bridge crane is suitable for warehouses and workshops in metallurgy, cement, chemical industries, and other enterprises. It is used indoors or in fixed outdoor spans for handling bulk materials such as limestone, ore powder, slag, coke, coal, sand, and minerals.

The crane mainly consists of the bridge frame, crane traveling mechanism, trolley, grab bucket, and electrical system. Its operating temperature ranges from –20°C to +40°C. The lifting device is a four-rope grab bucket with a double-drum mechanism, featuring simple structure and reliable operation. The grab can open and close at any height. It performs best when handling materials with particle sizes under 100 mm, offering high productivity. For materials larger than 200 mm, a toothed grab bucket is recommended. When used outdoors, the crane must be equipped with weatherproofing devices

GANTRY CRANE SERIES

QE Type Double-Trolley Bridge CraneThe QE-type double-trolley double-girder bridge crane is an upgraded version of the QD-type bridge crane, featuring two trolleys instead of one. It can operate with a single hook independently or both hooks simultaneously for lifting loads. This crane series is classified into medium-duty (A5) and heavy-duty (A6) working classes, and can also be custom-designed for light-duty (A1–A3) or extra-heavy-duty (A7–A8) applications if required.

The crane is operated from a cabin, which can be accessed via side, end, or top entry. The cabin offers a wide field of view and is equipped with an integrated control console, allowing flexible operation and comfortable working conditions. Optional features include fans, air conditioning, and overload indicators. A slanted ladder connects the cabin to the top of the crane for convenient operation and maintenance. Custom non-standard designs can also be provided based on user requirements

GANTRY CRANE SERIES

LH Type Electric Hoist Bridge CraneThe LH-type electric hoist double-girder bridge crane consists of an electric hoist trolley, bridge frame, crane traveling mechanism, and electrical control system. The lifting devices can be an electric hoist or chain hoist, with electric hoists available in single-speed (CD1 type) or dual-speed (MD1 type) options. The crane is designed for light-duty (A3) and medium-duty (A5) operation, with an operating temperature range of –20°C to +40°C.

GANTRY CRANE SERIES

LD Type Electric Hoist Bridge CraneThe LD-type electric single-girder crane is designed and manufactured according to JB/T1306-2008 standards. It is compatible with CD1 single-speed electric hoists, MD1 dual-speed electric hoists, and chain hoists, making it a rail-mounted light-duty crane.

GANTRY CRANE SERIES

YZ Type Metallurgical Casting Bridge CraneThe YZ-type metallurgical casting bridge crane is a primary lifting and transport device in steel mill smelting workshops. It features independently driven main and auxiliary trolleys. The main trolley is equipped with a fixed-spacing hook beam for handling molten steel, while the auxiliary trolley can be used for tilting molten steel or performing other auxiliary lifting operations.

GANTRY CRANE SERIES

QB Type Explosion-Proof Hook Bridge CraneThe LD-type electric single-girder crane is designed and manufactured according to JB/T1306-2008 standards. It is compatible with CD1 single-speed electric hoists, MD1 dual-speed electric hoists, and chain hoists, making it a rail-mounted light-duty crane.

GANTRY CRANE SERIES

LB Type Explosion-Proof Electric Single-Girder CraneThe LB-type explosion-proof electric single-girder crane is developed based on the LD-type crane and designed according to GB3836.1-2021 and GB3836.2-2021 standards. It is compatible with BCD, BMD, and other types of explosion-proof electric hoists, forming a rail-mounted light-duty lifting device.

This crane features a rational structure, attractive appearance, and strong explosion-proof performance, and is widely used in factories, warehouses, and storage yards of chemical enterprises.

GANTRY CRANE SERIES

LX Type Electric Single-Girder Suspension CraneThe electric single-girder suspension crane consists of a main beam and end beams welded from steel plates and I-beams, an electric hoist, and an electric trolley. It is suspended on the I-beam runway at the top of the workshop, with a cantilever length of 0.5–1 m. The electric hoist travels along the lower flange of the main beam’s I-section to perform lifting operations. The crane features a lightweight structure and easy installation and maintenance, and is widely used in production workshops, warehouses, and storage yards.

Electric Hoist Series

CD1 & MD1 Type Wire Rope Electric HoistThe wire rope electric hoist features a serial arrangement of the hoisting motor, drum assembly, and reducer, with a round or square appearance. It provides vertical lifting and traveling functions and is available as CD1 single-speed or MD1 dual-speed.

The dual-speed MD1 hoist adds a slow-speed drive system, consisting of a slow-speed motor and reducer, to the single-speed design, with a speed ratio of 10:1 between fast and slow speeds. When the fast motor operates, the slow-speed drive remains idle, allowing rapid lifting and lowering. When the slow motor operates, it drives the main hoisting motor’s conical rotor through the slow-speed drive, enabling slow and precise lifting and lowering.

Electric Hoist Series

Electric Transfer CartThe electric transfer cart, also known as an electric flat car, electric platform cart, trolley, gantry cart, or electric rail cart, is an electric material handling vehicle used within factories. It features a simple structure, ease of use, high load capacity, resistance to dirt and impact, easy maintenance, and long service life. Thanks to its convenience, durability, cost-effectiveness, practicality, and ease of cleaning, it has become the preferred transport solution for frequent short-distance handling of heavy loads within a factory or between factory buildings.